Efficient Water Management in the Semiconductor Industry

The semiconductor industry is a key driver of digitalisation and a resource-efficient economy. Due to the enormous water consumption in production, the requirements for modern and sustainable water management increase with every new production facility (fab) — especially in water-scarce regions such as Taiwan, Singapore, Texas or Arizona (USA).

Water as a Critical Production Factor

Semiconductor Industry

The semiconductor industry is a key driver of digitalisation and a resource-efficient economy. Due to the enormous water consumption in production, the requirements for modern and sustainable water management increase with every new production facility (fab) — especially in water-scarce regions such as Taiwan, Singapore, Texas or Arizona (USA). The industry faces growing social and regulatory pressure alongside stricter ESG requirements, while the critical role of water as a production factor makes innovative solutions indispensable.

Water demand in modern semiconductor fabs is increasing — with forecasts of a quadrupling by 2030 in Europe. Large-scale producers like TSMC require up to 99 million liters daily, demonstrating the need for efficient water cycles and the increasing importance of sustainable investments.

Sustainable water management is therefore becoming a strategic competitive advantage for the industry. Studies show that despite high water availability, Germany is already suffering from local water shortages, for example due to droughts, falling groundwater levels and pollutant inputs such as nitrates or PFAS. At the same time, regulatory pressure from the EU Water Framework Directive, national regulations and initiatives such as the Green Deal is constantly increasing.

According to the Scientific Advisory Board of the Federal Government on Global Environmental Change (Wissenschaftlicher Beirat der Bundesregierung Globale Umweltveränderungen, WBGU), water management is not only ecologically but also geopolitically crucial for security of supply and location stability. Companies that use water as a circular resource benefit from recycling, closed-loop systems and digital monitoring: These technologies reduce fresh water demand, increase resilience and improve regional acceptance.

The topic is becoming a location factor, especially in water-intensive areas such as semiconductor production, e‑mobility and the hydrogen economy. Sustainable use of water reduces costs and regulatory risks and strengthens competitiveness and innovative strength.

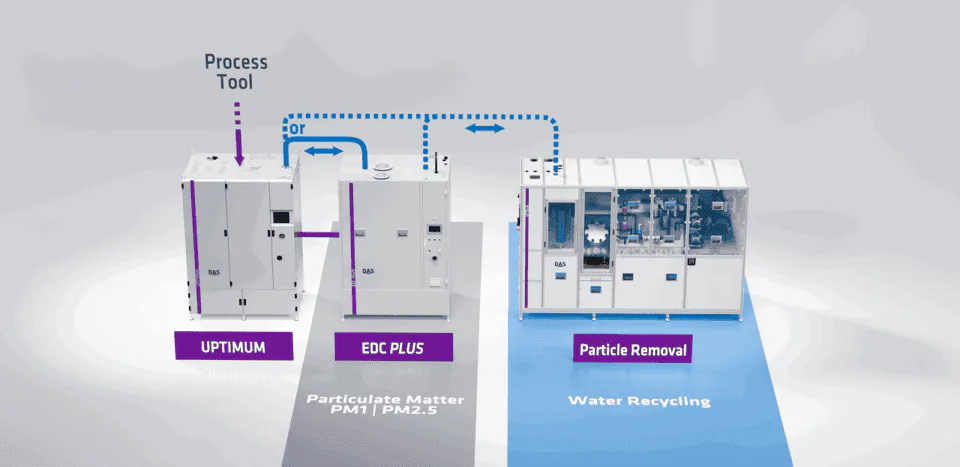

OTTELIA – Intelligent Wastewater Treatment Directly at the Point-of-Use

Efficient wastewater treatment in the subfab plays a key role in both saving and recycling water in semiconductor production. OTTELIA enables the reliable removal of silicon dioxide particles (SiO₂) from process wastewater. The combination of sedimentation and filtration allows the water to be reused directly in exhaust gas purification, effectively reducing the need for fresh water and reducing operating costs. OTTELIA is compact, scalable and quickly ready for use as a plug & play system. In this way, DAS Environmental Experts supports the achievement of company-wide ESG and stainability goals.

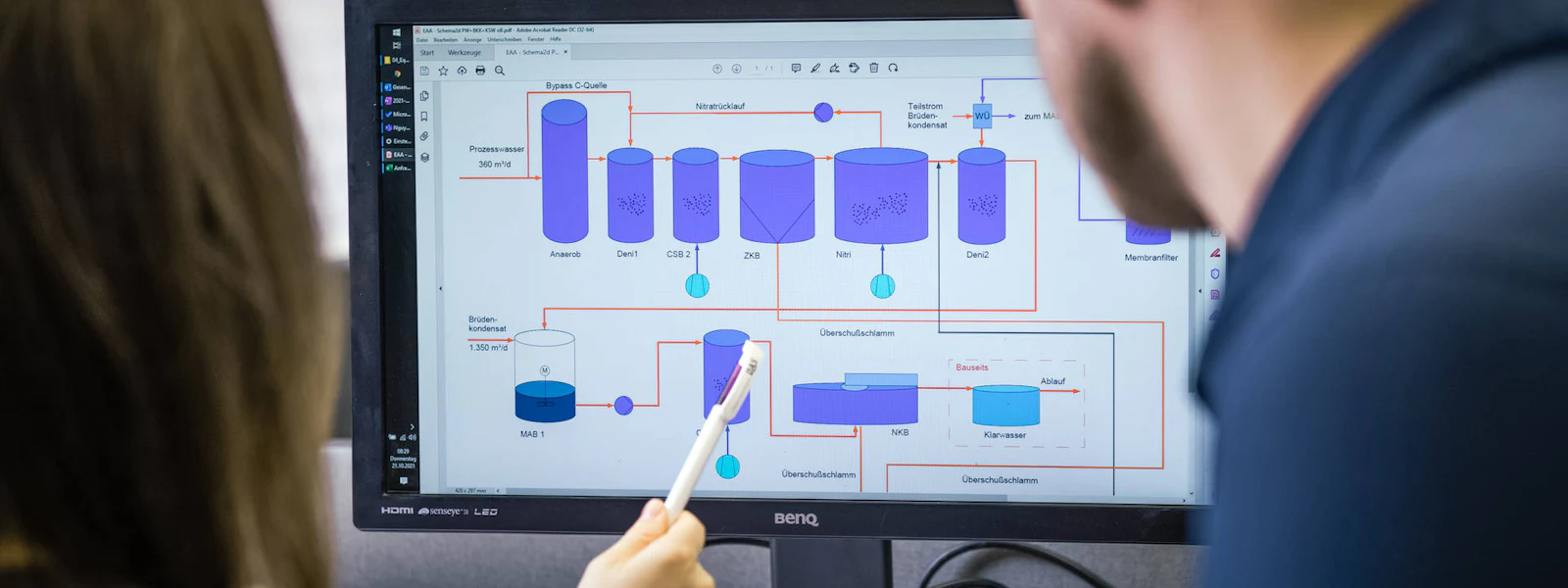

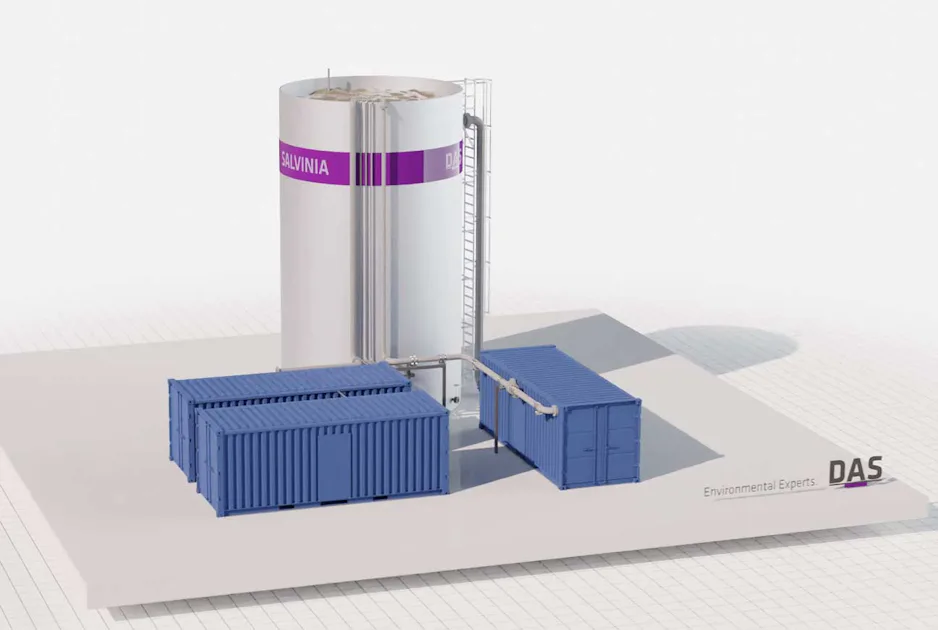

Moving Bed Biofilm Reactor – Biological Wastewater Treatment for Flexible Applications

With Moving Bed Biofilm Reactor (MBBR) technology, DAS Environmental Experts provides a robust solution for the biological treatment of semiconductor wastewater. Microorganisms on moving carrier materials minimize organic pollution even when input values fluctuate. The MBBR systems impress with their easy maintenance, modular capacity expansion and reliable process stability. The product range extends from the compact PoU system in the Sufab to scalable MBBRs in four standard sizes (SALVINIA) to the complete solution for the centralized or semi-centralized treatment of large amounts of wastewater.

From Wastewater to Resource

Technology Solutions from DAS Environmental Experts

The efficient use and reuse of water is both an ecological and economic necessity for the semiconductor industry. Technologies such as OTTELIA and MBBR significantly reduce water consumption and help companies to sustainably meet regulatory and social requirements. In times of global water scarcity, transforming wastewater into a resource becomes a decisive competitive advantage. DAS Environmental Experts makes a substantial contribution to resource-efficient and sustainable semiconductor production with tailor-made system solutions.

Learn more about our wastewater treatment here.