AQUABATE - Reliable Removal of Water-Soluble Pollutants

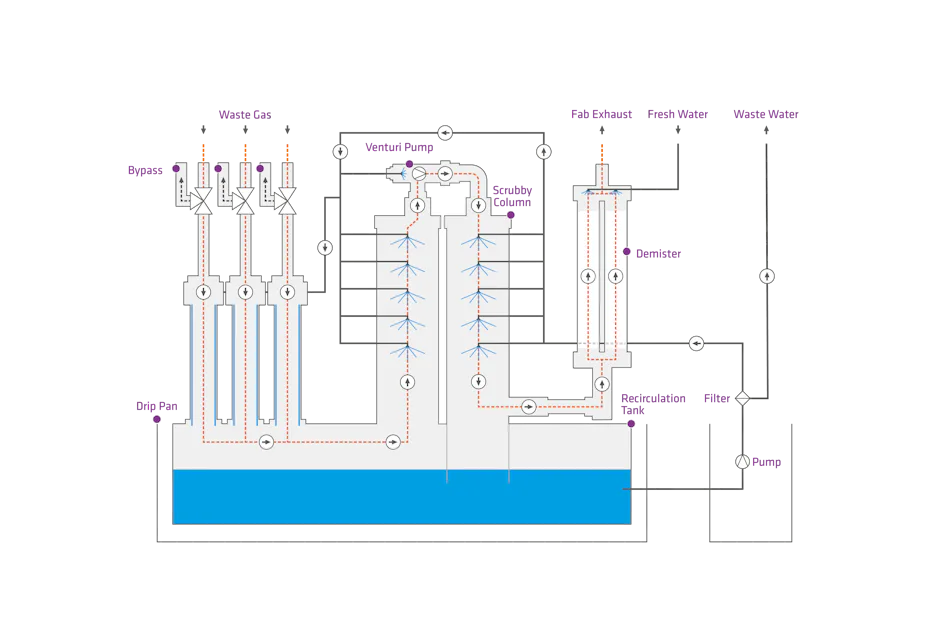

The well proven solution AQUABATE is a pure wet scrubber technology for flexible and customized abatement of water-soluble harmful substances from process waste gases at the point of use

Compact and Low-Maintenance AQUABATE Wet Scrubbers

Maintenance of AQUABATE wet scrubbers is quick and easy with access for operation and maintenance on the front and back sides. The cost-effective system requires only small space. Operation costs and general safety can be optimised with a process tool interface.

AQUABATE Product Family

AQUABATE EPI

AQUABATE EPI was specifically designed to treat waste gases of epitaxy processes in the semiconductor industry. The scrubber meets the high safety standards that are necessary when using hydrogen as a process carrier gas. After the scrubbing process, the hydrogen is safely diluted to its lower explosion limit. The waste gases are introduced through up to three separate connections, specifically designed to prevent blockages. Both inlets and feed lines have an optional heating system.

AQUABATE FLEX

AQUABATE FLEX is a modular wet scrubber for efficient treatment of water-soluble components from waste gases of different applications. The gas inlets are specifically designed to prevent blockages. AQUABATE FLEX is available as one- or two-stage scrubber. Based on the compact and modular design, the wet scrubber will be optimised to customer requirements. Depending on the configuration of the scrubber the gas inlets can be optionally heated up to the scrubber stage or the washing liquid tank in order to avoid problems caused by condensing gas in the waste gas supply. To increase washing efficiency the scrubbing liquid can be enhanced optionally with chemicals.

Optimise your waste gas treatment with AQUABATE

Reliably treats gases such as hydrogen chloride, chlorosilanes, ammonia and degradation products from etching processes.