TILIA – Dual Reactor System with Internal Redundancy

TILIA DUO is designed to efficiently handle the increasing process gas flows and can therefore replace several conventional exhaust gas cleaning systems.

TILIA – Waste Gas Treatment for Advanced Etch and CVD Applications in the Semiconductor Industry

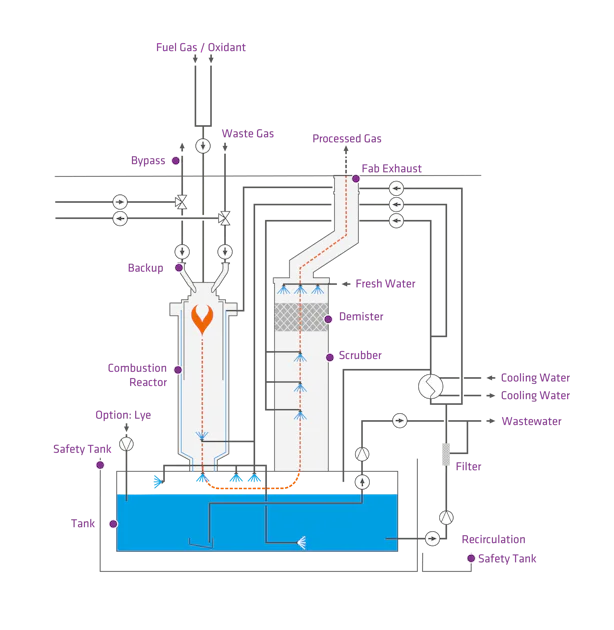

TILIA is a system for the disposal of pyrophoric, fluorinated, toxic or long-lived environmentally harmful gases and reaction products which are used in chemical and physical processes in the semiconductor and solar industry or are generated by the process. Disposal takes place via combustion and subsequent treatment in a scrubber, where particles are separated and soluble gas components are abated using a scrubbing liquid. TILIA offers outstanding efficiency in terms of footprint to throughput ratio. Operating costs can be optimized through the additional integration of a process tool interface.

Efficient Treatment of Industrial Processes with TILIA

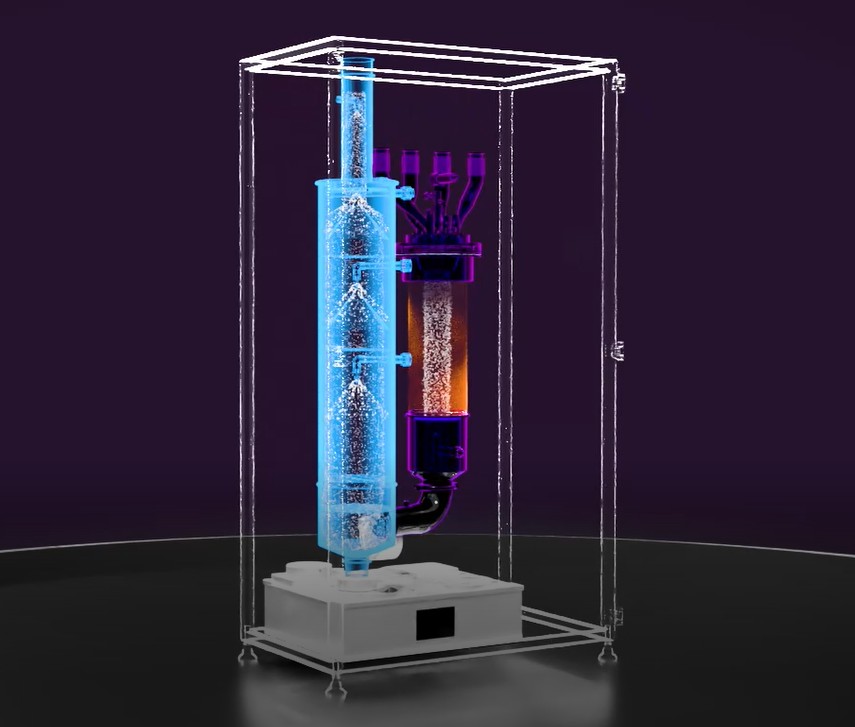

TILIA DUO

TILIA DUO contains two independent units, each consisting of one combustion reactor and one scrubber with an integrated demister located above it. Each unit also has its own power supply. TILIA DUO is available in the variants TILIA DUO 2+2, TILIA DUO 4+4 and TILIA DUO 6+6. Each unit has 2, 4 or 6 waste gas inlets as well as 2, 4 or 6 additional inlets, which are connected to the other unit via back-up lines. If necessary, the waste gas at the inlets of one of the two units can be diverted to the other unit. As a result, the system has internal redundancy and thus very high availability.

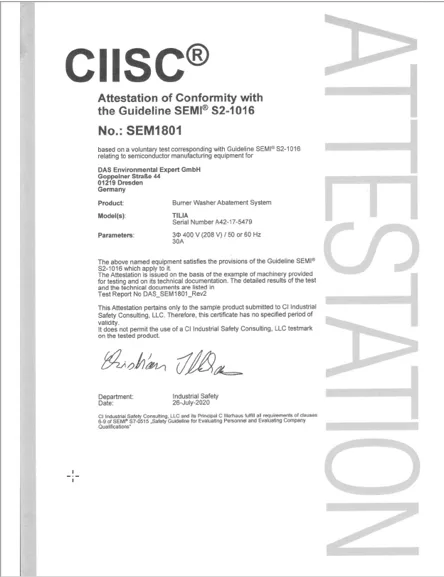

Best-in-Class Abatement System: TILIA Exceeds SEMI SCC Greenhouse Gas Benchmarks

DAS Environmental Expert GmbH reaffirms its leadership in sustainable semiconductor emissions control with independent validation showing that its TILIA abatement system achieves Destruction and Removal Efficiencies (DRE) exceeding 99.9% for CF₄ and other fluorinated greenhouse gases. This performance surpasses the targets defined in the 2024 SEMI SCC Whitepaper “Overview of F‑GHG and Nitrous Oxide Semiconductor Abatement Technologies,” which sets new industry benchmarks at a minimum DRE of >95% and an aspirational goal of >99%. TILIA proves that even higher efficiencies are not only technically feasible but deliver tangible sustainability and economic advantages.

Burn-Wet Technology for Safe Waste Gas Treatment

The compact burn-wet combination from DAS Environmental Experts is based on decades of experience in waste gas treatment. Process gases are oxidised, reduced or pyrolysed in a ring-shaped burner, depending on their composition. Subsequent wet scrubbing reliably cools and binds the resulting compounds. This point-of-use technology enables the safe and efficient treatment of industrial waste gases – including those containing fluorine compounds, ammonia, silane or hydrogen – and is used worldwide in the semiconductor industry.

Optimise Your Waste Gas Treatment with TILIA

Efficient treatment of pyrophoric, fluorinated, toxic or long-lived environmentally harmful gases and reaction products.