Efficient Wastewater Treatment for the Paper Industry

Efficient wastewater treatment and integrated heat recovery: Our case study at Schumacher Packaging GmbH shows how the E-PLATE heat exchanger can significantly reduce energy consumption in the paper industry.

Conserving resources through innovative heat recovery

The paper industry is one of the most energy-intensive sectors - wastewater treatment that reliably cleans and recovers energy at the same time is correspondingly important. At Schumacher Packaging, the use of the E-PLATE heat exchangerhow high solids and COD loads can be treated efficiently and how valuable heat from the process water can be utilized at the same time.

By combining thermal and chemical-physical processes, energy consumption is significantly reduced, operating costs are lowered and biological wastewater treatment remains fully efficient under stable conditions.

Case study: Heat recovery for stable processes at Schumacher Packaging

Schumacher Packaging produces new raw cardboard from waste paper at its Schwarzenberg plant - a process that requires large quantities of water and is heavily dependent on energy. The river water required for this from the Große Mittweida reaches the plant at only around 5 °C in winter and has to be preheated to production level. At the same time, increasing the capacity of the paper machine raises the process temperature to up to 55 °C - too hot for the subsequent biological wastewater treatment, whose microorganisms would die off.

There is also an official requirement: the treated wastewater must not reach more than 30 °C when discharged directly. This creates a double problem: the raw water, which is too cold, must be heated and the process water, which is too hot, must be actively cooled - both of which require a great deal of energy.

Conventional heat exchangers were out of the question for this application, as their transfer surfaces quickly become contaminated in the wastewater (fouling), the pressure loss is too high and complex cleaning cycles, including dismantling the equipment, would be necessary.

The E-PLATE waste water heat exchanger offers the ideal solution here:

It transfers the excess heat from the wastewater reliably and with low fouling to the cold river water. This cools the process water to a biologically compatible level, while the cold raw water is preheated in an energy-efficient manner.

This protects the biological stage from overheating, ensures compliance with legal temperature limits and significantly reduces the energy consumption of the entire system.

Why conventional heat exchangers fail - and the E-PLATE convinces

Conventional heat exchangers quickly become contaminated in contact with waste water, resulting in a massive loss of performance and high cleaning costs.

The E-PLATE was specially developed for these challenges and works with an open, flow-optimized design and continuous self-cleaning through rotating brushes.

This keeps the heat transfer stable, even with heavily contaminated waste water - without additional pumping stations, without complex CIP processes and without dismantling the appliance.

The most important advantages in brief:

Permanently high heat transfer performance without fouling

Minimal pressure loss and therefore no need for additional pumps

Particularly low-maintenance due to continuous self-cleaning

High operational stability even with wastewater containing fibers or solids

Significant energy and cost savings

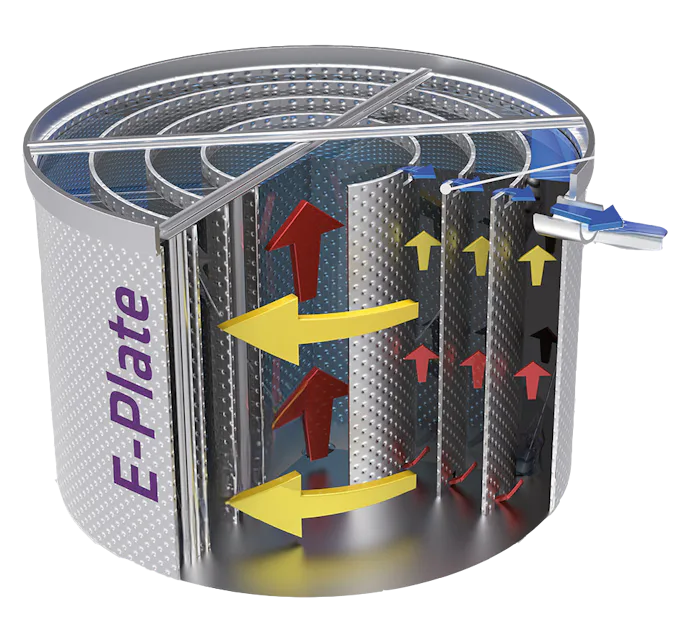

Functional principle of the E-PLATE heat exchanger

The E-PLATE waste water heat exchanger consists of several thermal plates arranged in a ring, which are constructed from double-walled, hydraulically expanded stainless steel plates. The cooling medium flows through these thermoplates in a circular pattern, ensuring uniform temperature distribution.

The contaminated waste water enters at the bottom of the heat exchanger and flows upwards between the plates. The rotating brushes work in this area, gliding continuously over the surface and removing deposits as they form. This self-cleaning not only effectively prevents fouling, but also creates a spiral flow that significantly improves heat transfer.

This spiral flow also creates the effect of a counterflow heat exchanger, without the need for narrower flow channels or additional pumping technology. In this way, the heat is transferred efficiently, the pressure loss remains extremely low and the performance of the device remains stable in the long term - even with heavily contaminated wastewater.

Installation at Schumacher Packaging

In Schumacher Packaging's waste water treatment plant, two E-PLATE-systems installed. The heat exchangers can be operated flexibly individually, in parallel or in series. This allows the system to be optimally adapted to different operating conditions, seasonal fluctuations and load changes.

This operating flexibility ensures that the biological stage is reliably protected from overheating - a crucial factor, as the microorganisms react sensitively to high temperatures and would die if the temperature limits were exceeded.

The result:

By using the recovered heat, external energy requirements could be massively reduced. Since the installation, Schumacher Packaging has saved around 40% natural gas, which meant that the investment paid for itself in the first year of operation. In addition, the cleaning processes have stabilized and overall energy consumption has fallen sustainably.

The performance data of the installed heat exchanger

Category | Output |

|---|---|

Heat output | 1 MV |

Flow rate — wastewater side | 65 m³/h |

Flow rate — cooling water side | 55 m³/h |

Pressure loss — wastewater side | 0,01 bar |

Pressure loss — cooling water side | 0,40 bar |

Further areas of application for the E-PLATE

The E-PLATE shows its strengths wherever high solids loads, fibrous media, temperature fluctuations or high energy consumption make wastewater treatment difficult. It is therefore ideal for:

Pulp and paper industry - recovering process heat despite high fiber loads

Textile industry and laundries - handling color, grease and textile abrasion

Petrochemicals and refineries - media with oil content, sludge and high temperatures

Biomass and sludge sector - utilization of waste heat from digested sludge

Anaerobic and aerobic wastewater treatment processes - preheating of the inlet or cooling of the outlet for optimum biological activity

Particularly in the anaerobic range, the E-PLATE can make the most of its advantages: Targeted preheating allows the operating temperature of 35-38 °C required for anaerobic reactors to be maintained with minimal energy input. This not only increases the reactor output, but also increases biogas production and improves the energy efficiency of the entire plant.

Your contact for energy-efficient wastewater solutions

Would you like to recover heat from your wastewater or optimize the energy efficiency of your system? Our experts develop individual concepts for maximum efficiency.