Heat Recovery as Key to Efficiency and Sustainability in Food Production

Food Industry

To significantly reduce energy consumption, Evers Special B.V., Europe's leading producer of fresh bean sprouts, relies on innovative heat recovery with the self-cleaning E-PLATE heat exchanger.

Evers Specials B.V.: Heat Recovery as Key to Efficiency and Sustainability in Food Production

Food Industry

Maximising energy recovery from the production process and thereby significantly reducing gas consumption – this was the task facing Evers Specials B.V. The Dutch company is a leading producer of fresh mung bean sprouts in Europe. Evers Specials commissioned DAS Environmental Experts to implement a self-cleaning heat exchanger (E-PLATE). The aim was to make efficient use of the heat contained in the production wastewater and to secure production in a sustainable manner.

Challenge: Utilising Energy Potential in Wastewater

Evers Specials has been one of Europe's leading producers of mung bean sprouts for almost 60 years. The company currently employs around 120 people. From its location in Nijmegen, the company supplies industry, retail and catering businesses within a radius of around 800 kilometres – including Germany, Belgium, Denmark and northern France.

The cultivation and processing of sprouts is water- and energy-intensive. Fresh water is heated for growing the sprouts, and the freshly harvested sprouts are cleaned and cooled before shipping. The wastewater from sprout cultivation has a temperature of 21°C. Using this usable energy instead of primary energy is a challenge that Evers Specials took on in 1998 with the purchase of a conventional heat exchanger for heat recovery. However, this heat recovery system had to be taken out of service due to its high susceptibility to contamination, complex cleaning and technical malfunctions.

“The self-cleaning properties of the E-PLATE were a key factor for us. The system runs silently and reliably without any malfunctions, thus contributing significantly to the stable operation of our production process.”

Self-cleaning Heat Exchanger E-PLATE for Wastewater Containing Solids

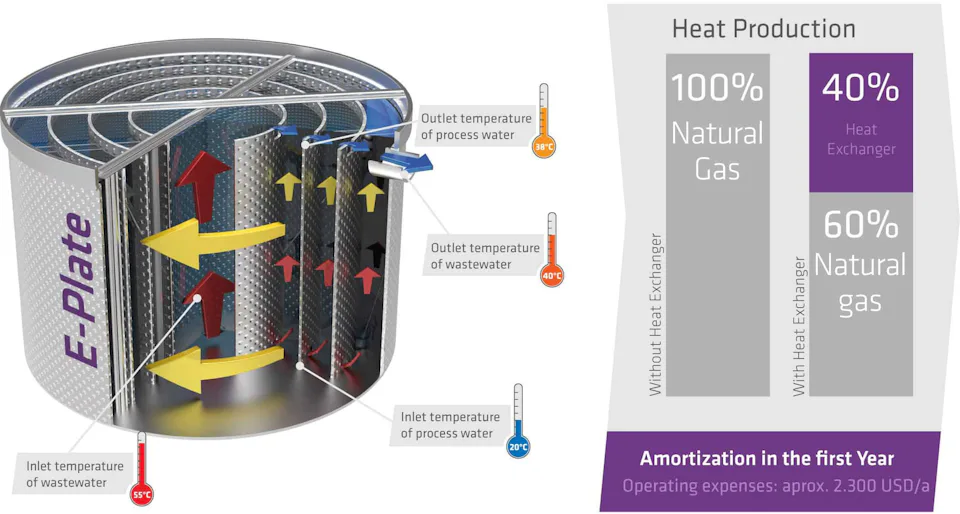

In the search for a robust, low-maintenance alternative, the decision was made in favour of the E-PLATE from DAS EE, a heat exchanger developed by the Dresden-based company specifically for wastewater containing solids.

Parallel to the installation in the existing production and cooling system, Evers Specials commissioned a central ammonia plant as a heat pump. This improved the temperature differences in the overall process and increased the efficiency of heat recovery. The Dutch government subsidised the energy-efficient recirculation of waste heat from the refrigeration system for use in heating fresh water.

Technical Features of E-PLATE

Self-cleaning thanks to rotating brushes that continuously keep the plate surfaces clear

Optimised heat transfer thanks to turbulent flow with low pressure loss

Robust design with large plate spacing (approx. 12 cm) to prevent blockages

Easy integration without complex control technology

This design allows heat from the wastewater to be transferred continuously and efficiently to fresh water – even with fluctuating loads and high solids content.

Integration and Added Value for Production

E-PLATE operates bidirectionally: it can both extract heat from the wastewater and dissipate excess heat. The system thus performs three key tasks:

1. Cooling of cold storage rooms,

2. Support for vacuum cooling in batch operation,

3. Heat pump operation for utilising process heat.

The system is designed to ensure that pump capacities and temperature differences always remain in balance. This ensures that all sub-processes operate within the optimum parameter range – without interrupting production.

Stable Performance and Economic Benefits

Since commissioning, the E-PLATE has been operating smoothly and with consistently high heat transfer. From October to March, the system saves around 10,000 cubic metres of gas per month. As part of a comprehensive modernisation project, it contributes significantly to reducing energy costs and improving the carbon footprint. With the help of this technology, CO₂ emissions can be minimised by around 107 tonnes of CO₂ in the winter months alone.

Further Optimisations planned

Evers Specials continues to work with DAS Environmental Experts on optimising energy and resource efficiency. In addition to process heat, solar energy is also to be used more extensively in future. Further DAS EE systems are already in the planning stage. The aim is to cover even more of the energy supply from own sources and to further develop production in a sustainable manner.

Conclusion: Energy-efficient Heat Recovery as a Success Factor

By using self-cleaning wastewater heat exchangers such as the E-PLATE from DAS Environmental Experts, food producers can sustainably improve their competitiveness, energy efficiency and carbon footprint. Practical user examples such as Evers Specials demonstrate the benefits and cost-effectiveness of this technology.

Your Contact for all Questions regarding E-PLATE

For further information please get into touch with our Environmental Experts