Energy Recovery from Wastewater with E-PLATE

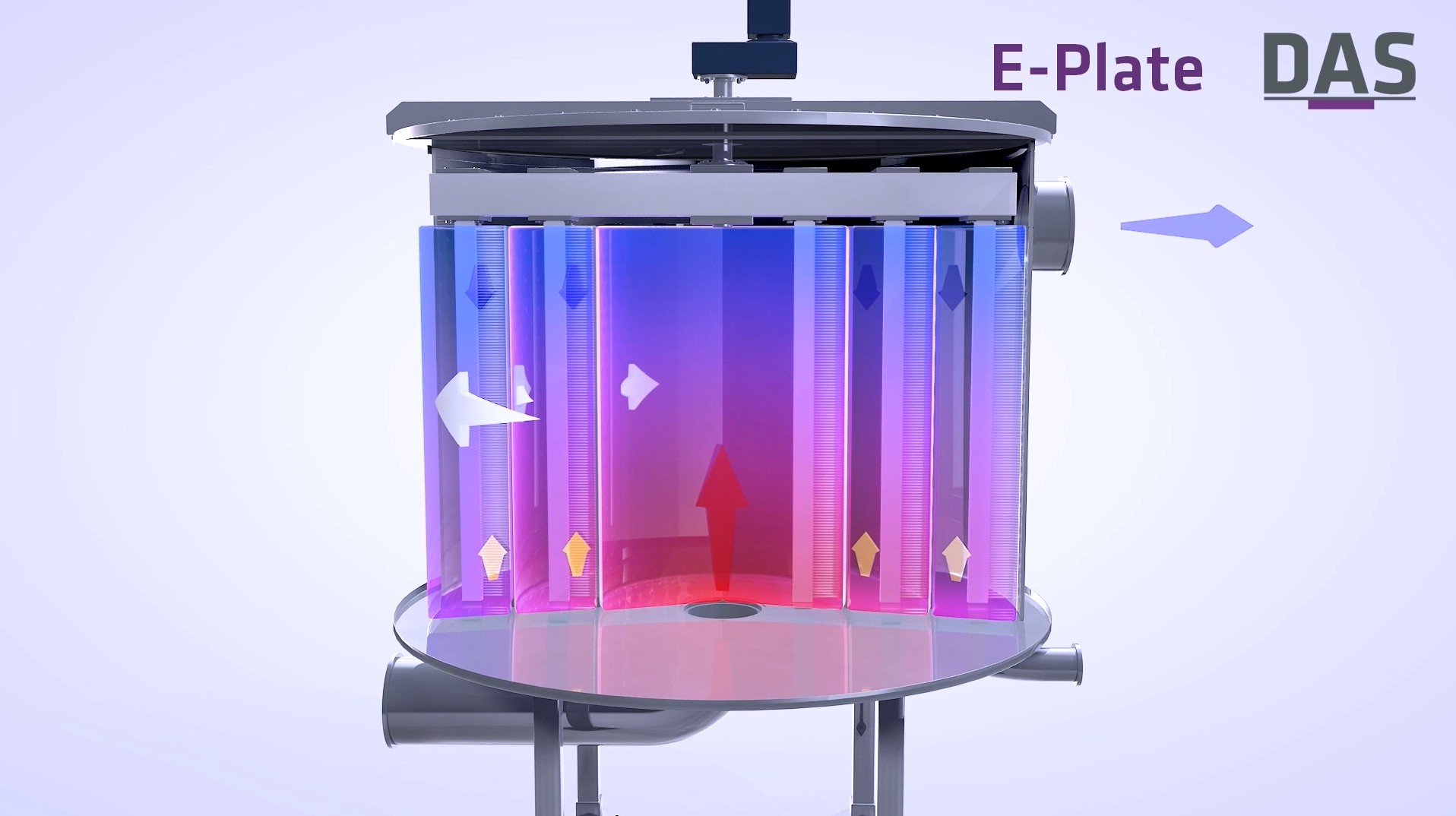

E-PLATE enables efficient cooling and heat recovery even with wastewater containing solids – for stable processes, higher energy efficiency and increased plant performance.

E-PLATE — the Heat Exchanger for Wastewater Contaminated with Solids

Efficient. Sustainable. Future-oriented.

Thanks to innovative technology, the E-PLATE offers versatile potential uses in various industries — from paper to food.

Water temperature plays an important role in the effective treatment of wastewater streams at the various treatment stages. For example, partial flows that are too cold are a problem, especially for anaerobic reactors, as the bacteria require a minimum temperature for their metabolism. If the water is too warm when it enters the biological treatment stage, this can have a negative impact on the biology.

Cooling towers and falling film coolers used to be the preferred method for cooling process water. But why waste valuable heat energy? An E-PLATE plate heat exchanger can be used to cool wastewater while increasing the energy and performance efficiency of the plant.

In addition to the efficiency of their purification, operators of wastewater treatment plants also keep an eye on the social aspects of water flows. To protect adjacent waters and the organisms living in them, there are public regulations governing the temperatures that must be maintained during direct discharge. As a rule, the lower and upper water authorities determine the temperatures to be maintained on a case-by-case basis. In Dresden, for example, there is an upper limit of 35 °C.

Another important aspect is the development of odours due to warm flows in the sewage system. Depending on the outside temperature, this phenomenon can be exacerbated and cause a nuisance to residents.

Highly Efficient Operation

Our E‑PLATE heat exchanger can be incorporated into the planning of your new wastewater treatment system from the outset or installed retrospectively to optimise existing wastewater systems.

The following video gives you an insight into how the E-PLATE heat exchanger works and how it is integrated into a wastewater treatment plant in the paper industry.

Wastewater Treatment & Heat Recovery in the Paper Industry

Your Advantages – Why E-PLATE?

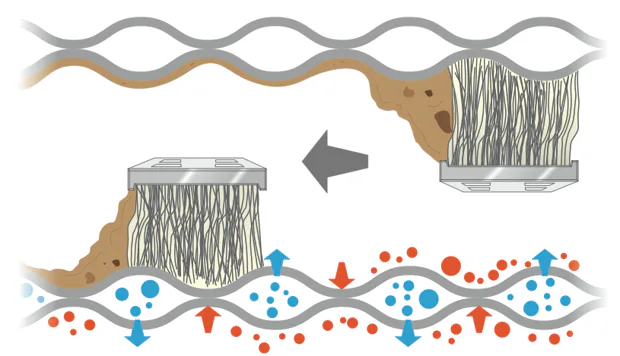

Permanent self-cleaning: Saves maintenance costs and prevents blockages.

Low pressure loss: For smooth operation.

Easy retrofitting: Ideal for existing and new systems.

Suitable for wastewater containing solids: Reliable even under difficult conditions.

Durable and robust: High-quality materials for a long service life.

Higher energy efficiency: Utilise wastewater heat and reduce energy consumption.